Because of the two-lamps illumination, which is exemplary for the early epoch 3, I got the idea to put backlights into the tender. This is good for night trips without trains. The 41 has, in opposite of other steam locos of Maerklin, a coupler at the front. So it is possible to push a train forwards while a front loco is pulling. This only works if both locos has a decoder with regulation and both must be set exactly to the same speed and delay.

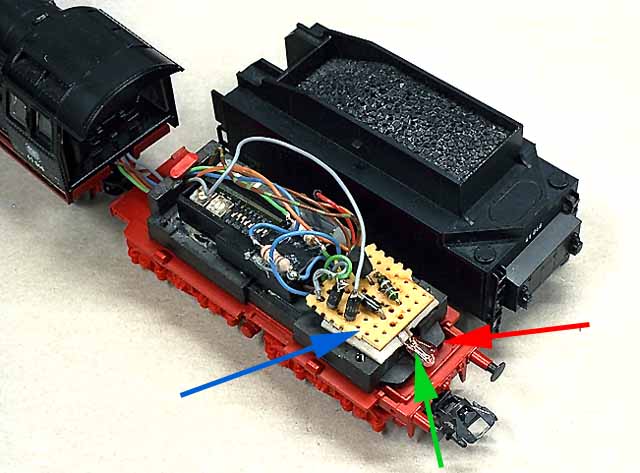

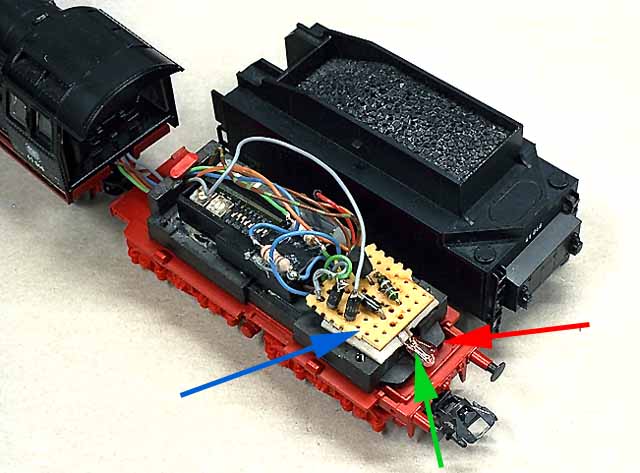

First I bought a lamp socket 25 99 20 und glued it into the pit of the ballst weight. This will hold the red bulb (red arrow). On the photo it is not good to see, because it is hidden behind the white bulb (green arrow).

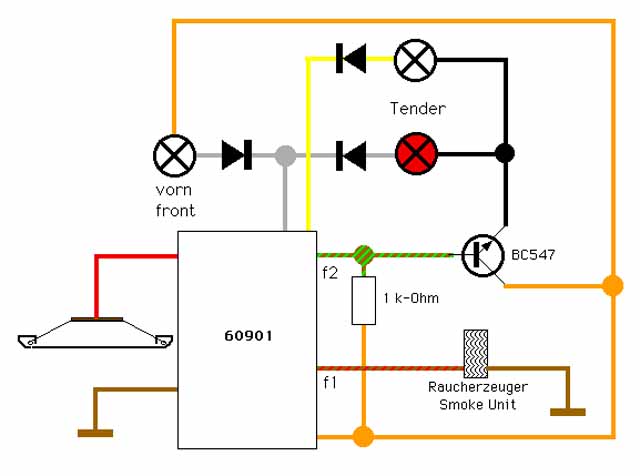

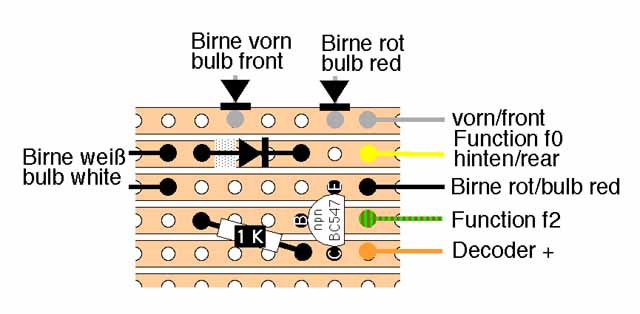

If the loco is pulling a train, it is normal to switch off all lights at the tender. This is the same like with the locos for shuttle trains. I soldered some electronic stuff onto a small circuit board with connecting stripes (similar to a breadboard) (blue arrow) and wired all as shown at the grafic. I soldered the white bulb without socket to the circuit board (green arrow). The function f2 switch off the two bulbs.

The photo shows how the red lights looks. If the white lights have a pink color while driving backwards, a black piece of paper must be placed between the two bulbs. To get the best illumination the red bulb must be placed directly under the white one.

In between I have two locos 41 and both has problems in curves with 360 mm radius. The reason is the chassis, which is not separated in two bogies like the locos 50 and 44. If my 41 drove with a heavy train on a curve turnout, the first driven wheels derailed always. I noticed, that sometimes the first driven wheels has no contact to the rails.. I f the train is coupled to the front, and the loco drives backwards, all works well. The loco has not enough weight at the front side.

To weight the loco, first I removed the body. The boiler is made of metal, but not solid. The botton is closed by a plastic part. I was not able to removing it, without destroying something. So I cut a hole into it and put some lead into the boiler. After it I closed the hole withe the plastic part and some glue. The heavier loco runs much better und never derailed again on curve turnouts.

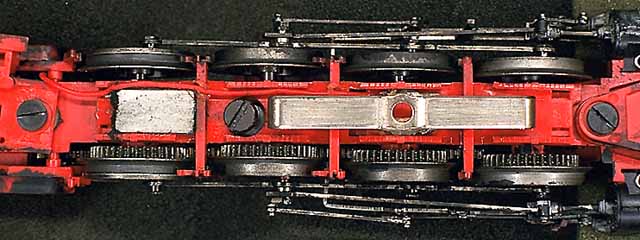

Usually I put the second pickup shoe under the second bogie of the tender. This solution is not perfect, because the tender can derail while fast driving backwards. If two pickup shoes are near together, the contact is not so good. I tried to put a second pickup shoe from Roco 40003 between the driven wheels. The results are positive, because the loco is heavy enough now. The contact is better and the are no drailings on curve turnouts.