Problems with contact can occur anytime. It is sometimes necessary to improve the power take off, so locomotives can drive really slowly across dirty rails and turnouts. This is quite simple with electric locomotives. You only have to connect the catenary system to the same circuit as the point contacts in the center of the rails. Then you need to solder a wire to the switch in the locomotive, so that the pantograph is connected to the pick up shoe. If ever the shoe has no connection with the point contacts, power and digital data will flow through the pantograph.

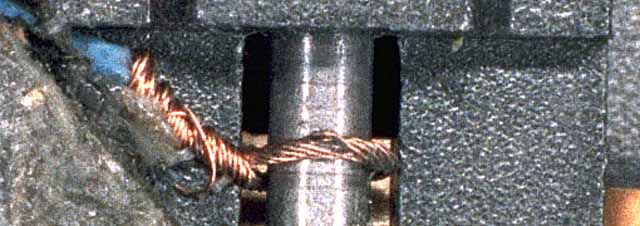

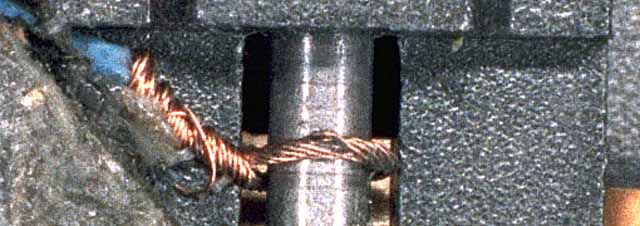

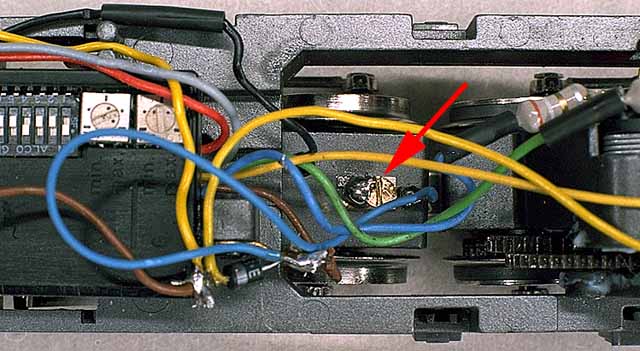

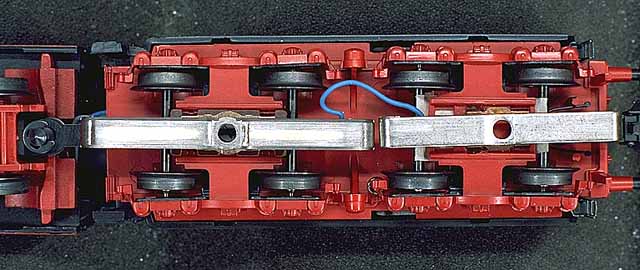

With my shunting engine BR 160 (3457) the problem was with the contact to the ground. Though the first axle has a contact plate (blue arrow), the connection was lacking, due to the accumulated oil and dirt. Continual cleaning and re-bending of the contact plate brought only short-term improvements. I wrapped a stranded wire around this axle (green arrow) and soldered the other end to the ground terminal at the motor housing. There was a similar problem with the BR 152 (3366). The suspension part and wheels, on the side without motor, had only occasional contacts and the front axles could not compensate for this. I drilled a hole from the top into this part of the suspension, inserted a screw and soldered a ground cable to it (red arrow). Due to the additional ground contacts, combined with the power take off through the pantograph, both locomotives now operate without any problems.

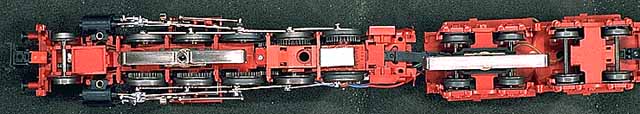

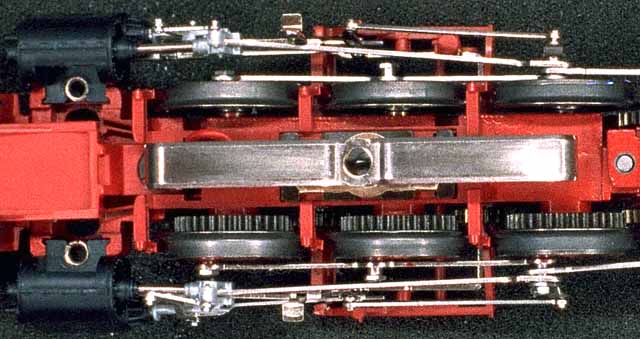

My steam locomotive BR044 (37880) often stopped, when I tried to drive it slowly across the turntable. I corrected this annoyance by installing a second pick up shoe 7164 between the powered wheels. The grove and a threaded screw hole are already there and it doesn't take long to solder a wire. Mind you, the initial test drive was rather disappointing. The locomotive drove much more jerkily than before, since it hardly had any contact with the ground at all. Since only the powered wheels are connected to the decoder and the locomotive was pushed slightly upwards due to the additional pick up shoe, the electric connection to the rails was poor. I then soldered wires to both suspension sections of the tender and connected them to the ground wire of the decoder. To provide good contacts to the solder points on the suspension, they need to be roughed up somewhat with a piece of sandpaper or with a small grinding tool. Now it is a joy to drive this locomotive slowly and completely free of any jerking motion across the turntable.

It is also quite easy to mount a second pickup shoe on the insider locomotive 52 with condensation tender (37171). The ground pickup shoe has to be removed from the rear suspension and a pickup shoe (206370) has to be inserted. To allow for free movement of the pickup shoe, I had to melt part of the box on the bottom of the tender with a soldering iron. This alteration is not noticeable from the outside. The wire on the decoder must be changed accordingly, to avoid a short. Naturally, this locomotive now had problems with ground contacts and I had to solder an additional ground wire to the suspension of the tender.

Steam locomotives equipped with tenders that have four axles, such as the 003 or the 041 (3082, 3792, 3085, 3795, 3097 and others) can also be modified to accept a second pick up shoe. However, only the short shoe from Roco (40003) will fit here. I removed the small Pertinax plate and attached the shoe directly to the suspension, by bending the metal corners. Two of the four holes in the rear suspension had to be made somewhat longer, to allow for the change. With a thin wire I connected both pickup shoes. There were no more ground problems with my 003.

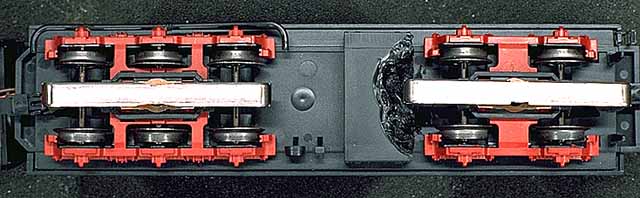

For a long time I didn't know what to do about my diesel locomotives. With the V188 it is fairly simple, since one can insert the pickup shoe 206370 underneath the second half of the locomotive. Locomotives of the series V100 (3072, 3714, 3437, 33723 and others) or series V160 (3074, 3075, 3679, 3373, 33743 and others) are more difficult. Required is a short pickup shoe 7164. The Pertinax plate needs to be removed and the now superfluous brass tongues have to be cut off. Then you have to attach a strip of double sided adhesive tape under the suspension with the motor and press the pickup shoe onto the tape, exactly in the center to the driving direction. It is important to ensure that the pickup shoe has no contact with the transmission block. A wire needs to be soldered to the pickup shoe and routed between motor and frame to the inside of the locomotive. Later you can paint the light colored adhesive strip with dark gray or black paint.

With locomotives of the series V200 (3581, 3682, 3380, 3384 and others) the change is somewhat more difficult, since the clearance underneath the engine suspension is quite small. The problem here is the holding bracket and the screw. With a small grinding disk I removed about 1 mm of metal. I covered the gears and other sensitive parts of the locomotive, to prevent damage from the metal filings. To allow for later removal of the screw, I removed it and modified the counter sinkhole, so that the screw can be turned in deeper. As with the other diesel locomotives, the pickup shoe is attached with double-sided tape.